Product Description

MAIN FEATURES

MAIN FEATURES

● Samples: Powder, flag sample, others available upon request

● Optional interconnection with XPS, STM and other ultra-high vacuum system

● Process Chamber, heating up to 400℃, temperature control accuracy ±1℃

● Up to eight different precursors, two oxidation/reduction lines, and three carrier gas lines

● High-temperature bubbler design for solid metal precursors with low vapor pressure, ideal for improving reaction efficiency and experimental repeatability

● Automatic control system, programmable process control to achieve automatic sample growthThe control ● system has a safety interlock alarm function

● PID control algorithm with auto tuning function

● All metal sealing, ideal for corrosive reaction process

● Real time gas flow and vacuum monitoring

● On-line residual gas analysis module

● Including zone generator and thermal decomposition device for reaction residuals

● Samples: Powder, flag sample, others available upon request

● Optional interconnection with XPS, STM and other ultra-high vacuum system

● Process Chamber, heating up to 400℃, temperature control accuracy ±1℃

● Up to eight different precursors, two oxidation/reduction lines, and three carrier gas lines

● High-temperature bubbler design for solid metal precursors with low vapor pressure, ideal for improving reaction efficiency and experimental repeatability

● Automatic control system, programmable process control to achieve automatic sample growthThe control ● system has a safety interlock alarm function

● PID control algorithm with auto tuning function

● All metal sealing, ideal for corrosive reaction process

● Real time gas flow and vacuum monitoring

● On-line residual gas analysis module

● Including zone generator and thermal decomposition device for reaction residuals

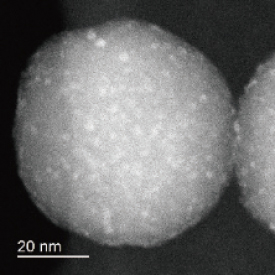

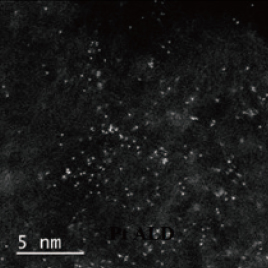

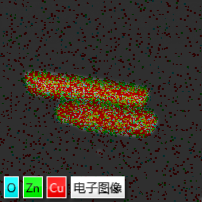

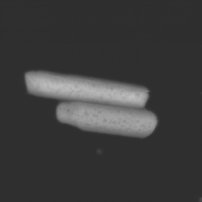

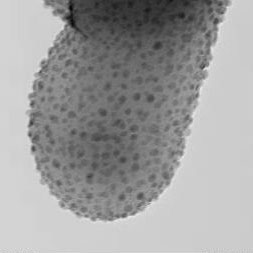

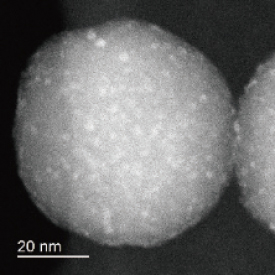

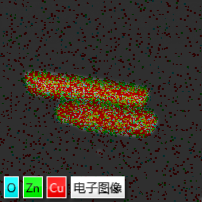

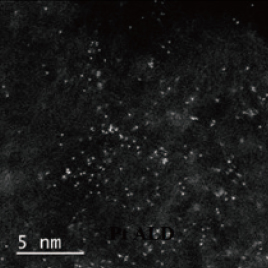

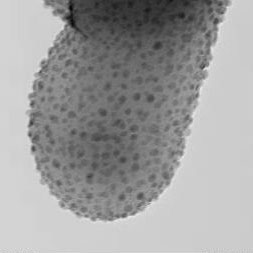

ALD TEST DATA

ALD TEST DATA

TECHNICAL DATA

TECHNICAL DATA

| Main Chamber | Size | ID 40mm × L 980mm or custom upon request |

| Material | 316SS | |

| Heating Temperature | RT~400℃ | |

| Temperature control accuracy | ±1℃ | |

| Precursors Delivery | 4 Low temperature precursors (RT~80℃) | (CH3)3Al, (CH3)3Ge, H2O etc. |

| 4 High temperature precursors (RT~300℃) | Fe(Cp)2, Precious metal precursors |

|

| Temperature control accuracy | ±1℃ | |

| Gas Flow Control | 5 Gas flow controllers, 0-500 sccm | |

| Carrier Gas | N2, Ar | |

| Reaction Gas | O2/O3,H2 | |

| No. of Temperature Control | 48(Max), Temperature control accuracy ±1℃ | |

| No. of Valve Control | 24(Max), Control accuracy 15ms | |

| Control System | Main processing unit, heating control unit, temperature control unit | |

| Software Control | LabVIEW graphical design, PID temperature control with fuzzy algorithm auto tuning function, Programmable and Vacuum interlock function |

|

| Options | Residual gas analysis module | |

| Plasma module | ||

| QCM for in-situ gas composition analysis | ||

| Ellipsometer optical detection module | ||

| FTIR spectrum in-situ detection module | ||

Related Documents / DOWNLOAD

Related Products